Four Decades of Innovation: Issues 26 - 60

No. 26 - 1975

No. 26 - 1975

Protecting Lives in Highrises

Little Tokyo Towers is the first high rise built in Los Angeles under new state and city fire codes, which require automatic fire sprinklers to be installed in newly constructed buildings over 75 feet tall. An all-copper "Life Safety System" protects residents of the 16-story residential tower.

No. 27 - 1976

No. 27 - 1976

Residential Plumbing Solutions

Challenged by a modern interior design in the house he is plumbing, a Denver contractor becomes the first to introduce a new commercial plumbing product into a singlefamily home. An open floor plan in the kitchen left few options for venting the plumbing drain out of view. The plumber used an innovative self-aerating copper pipe called Sovent, which does not require a separate vent pipe to the outdoors to keep from marring the modern interior decor.

No. 28 - 1976

No. 28 - 1976

Lightweight Sprinkler Systems

Citing ease-of-use over steel piping for residential sprinkler installations, the head of Acme Automatic Sprinkler, located just outside Philadelphia, chooses an all-copper sprinkler system for the 21-story residential Regency Towers condominium building in Ventnor, New Jersey. The contractor says copper systems take less than half the time for installation as steel systems.

No. 29 - 1976

No. 29 - 1976

Solar is Booming

Skyrocketing energy costs have consumers scrambling for alternative solutions to heat their homes and provide domestic hot water. The number of new, all-copper solar collector manufacturers also climbs - fueled by industry recognition of copper's superior performance and quality for this application.

No. 30 - 1976

No. 30 - 1976

Fast Food Chain Installs Sprinklers, Fast

The popularity of fast food restaurants prompts concern for diner safety. Burger King Corporation announces that its 2,000 locations would be outfitted with allcopper fire sprinklers by 1980. Director of Safety Donald Herbstman says the company chose copper because installation time is one-third faster than with other piping systems.

No. 31 - 1977

No. 31 - 1977

Urban Co-ops Try Solar Energy

Twenty-five turn-ofthe- century residential co-op buildings in New York City's most disadvantaged neighborhoods are slated to "go solar," thanks to assistance from a private group called the Energy Task Force. Tenants provide the work equity to install all-copper solar panels while government funding pays for the equipment.

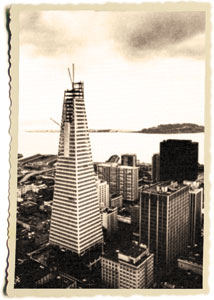

An all-copper fire safety sprinkler system is installed in San Francisco's Transamerica Building, the tallest building on the West Coast.

An all-copper fire safety sprinkler system is installed in San Francisco's Transamerica Building, the tallest building on the West Coast.

No. 32 - 1977

No. 32 - 1977

Capitol Copper Construction

More than 30,000 pounds of copper are used to re-roof the Arizona State Capitol Building in Phoenix. The building's dramatic dome is covered in 6 copper that has a special clear finish, called Incracoat (developed by the International Copper Research Association), applied to its surface to ensure that its original coloring never fades.

No. 33 - 1977

No. 33 - 1977

Vegas Hotel Plumbing Is No Gamble

Las Vegas casino hotel construction booms with the help of a new, easier-to-install copper Sovent plumbing system. An 800-room addition to the Flamingo Hilton and the all-new Las Vegas Hilton benefit from the self-aerating plumbing system, which eliminates the need for separate vent stacks, saving time and cost of installation.

No. 34 - 1978

No. 34 - 1978

Trio of Building Systems

Danbury Hospital in Connecticut builds a nine-story addition that is the first known structure to incorporate three new all-copper building systems: A copper solar energy system, all-copper automatic fire sprinklers and an all-copper Sovent plumbing drain system. In addition, copper tube is used throughout for water distribution and drainage, air temperature control, clinical air for intensive care patients and snow - melting equipment.

No. 35 - 1978

No. 35 - 1978

Solar-Powered Fire Station

The country's first fully solar-assisted fire station is constructed in Dallas, Texas. Fire Station #1 uses 60 all-copper solar collector panels to provide 75 percent of its hot water, 50 percent of its cooling and 40 percent of its heating. To encourage residents to learn more about solar power, appointments are scheduled to allow the public to view the system.

No. 36 - 1978

No. 36 - 1978

Cost-Saving Plumbing Systems

Self-aerating copper Sovent plumbing drain-vent systems continue to demonstrate the installation speed and cost-saving attributes of these prefabricated products. Projects in the news range from a new 1,000-room MGM Grand Hotel in Reno to a 100-room retirement home. All benefit from an estimated 30 percent in savings over conventional drainage systems.

No. 37 - 1978

No. 37 - 1978

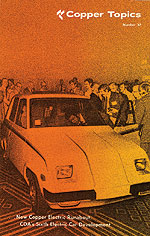

Trial Transportation

The Copper Electric Runabout is CDA's latest electric vehicle prototype designed to reduce pollution and gas consumption. With a 14-hp electric motor powered by eight leadacid batteries, it has a top speed of 59 mph, a city driving range of 79 miles (with stops), and a cruising range of 72 miles at 40 mph. Designed to sell for $5,000 and be used as a second car, it is introduced at the Fifth International Electric Vehicle Symposium.

Close-up of floats used by Marifarms in the Gulf of Mexico for six months shows copper's ability to resist bio-fouling (the growth of harmful marine life) while Styrofoam floats are covered by barnacles.

Close-up of floats used by Marifarms in the Gulf of Mexico for six months shows copper's ability to resist bio-fouling (the growth of harmful marine life) while Styrofoam floats are covered by barnacles.

No. 38 - 1979

No. 38 - 1979

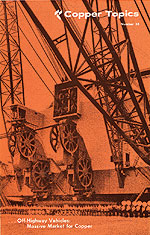

Motors for Machinery

Statistics show that copper use for industrial and farm machinery and mining equipment totals 45 million pounds annually. Most of the copper is used in electric motor windings. Electric forklifts, which have up to four separate motors, consume 8.7 million pounds. Draglines for mining and construction use 2.7 million pounds - one 5,000,000-pound dragline alone requires 120,000 pounds of copper in motors and generators, 30,000 pounds in wiring and more than 4,000 pounds in bronze bearings and bushings.

No. 39 - 1979

No. 39 - 1979

Ode to Copper

Two Arizona hotels use copper throughout to attract guests by projecting an image of beauty and to suggest Arizona's copper mining history. The San Carlos Hotel incorporates copper-clad doors, elevator facades, ceilings and planters. The Fiesta Inn uses 15,000 square feet of copper in the building's facade, exterior and interior lamps and in walkways to guest rooms, while the inn's bar, tables, countertops and food trays are all copper-clad.

No. 40 - 1979

No. 40 - 1979

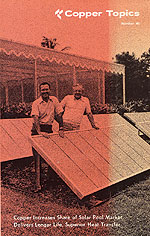

Solar Swimming Pools

More than 1,000 copper solar panel installations are reported to be heating swimming pools in homes across the country, and many systems coordinate pool heating with home hot water and space heating and cooling. The systems demonstrate copper's superior heat-transfer capability and long lifetime over plastic solar panels, and fewer copper panels help to reduce materials and installation costs. Consumers also realize savings more quickly, as payback on combined pool/home heating is reduced in many cases to less than two years.

No. 41 - 1979

No. 41 - 1979

Solar Apprentice Program

More than 10 million pounds of new copper will be needed to supply 75% of the expected 115,000 solarpower installations this year, according to CDA estimates. In a project conceived by CDA, the National Association of Plumbing, Heating and Cooling Contractors will train more than 50,000 apprentice plumbers - by having them install copper solar panels on the roofs of their training schools.

No. 42 - 1980

No. 42 - 1980

Reliable Energy Production

As America's growing need for energy prompts calls for bigger power plants, engineers are specifying copper alloy condenser tubes in their cooling systems to handle the higher temperatures and greater water velocities they must accommodate. The use of 90/10 and 70/30 copper-nickel alloys offers increased reliability and higher performance. Light-wall copper alloy tube not only provides an economic advantage, it also has distinct advantages of high heat transfer and anticorrosion properties.

No. 43 - 1980

No. 43 - 1980

Improved Fuel Efficiency

In a continuing effort to reduce vehicle weight, and thereby realize greater production efficiency and consumer fuel savings, manufacturers show renewed interest in highly capable, lighterweight copper radiators. One promising advance is a new soldering process that is lighter, stronger, has higher conductivity, and costs less than current lead-tin solders.

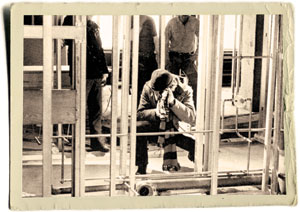

The copper Sovent self-aerating plumbing drainage system simplifies installation while reducing construction costs. Here, a photographer shoots a training film for CDA on the new technology, which is heralded as a breakthrough in building construction by the New York State Urban Development Corporation.

The copper Sovent self-aerating plumbing drainage system simplifies installation while reducing construction costs. Here, a photographer shoots a training film for CDA on the new technology, which is heralded as a breakthrough in building construction by the New York State Urban Development Corporation.

Nos. 44 and 45 - 1980 and 1981

Nos. 44 and 45 - 1980 and 1981

Energy Showhouse

The third in a series of copper showcase homes opens. Extensive use of energy- saving features throughout the home includes high-efficiency window glazing and increased insulation to supplement built-in solar-energy collectors. The Sun/Tronic "idea home" gets 45 percent of its space and water heating energy from the sun, while photovoltaic cells provide 5 percent of its electrical power. A novel heat exchanger reclaims waste heat from the heat pump to also heat domestic water.

No. 46 - 1981

No. 46 - 1981

Long-Lasting Roof Shingles

A long-time producer of aluminum roof shingles begins offering easy-to-install copper shingles, citing copper's extremely long life and high aesthetic appeal. The manufacturer, Zappone, notes that the 99% pure copper materials are more expensive to purchase and install at $3.80 to $5 per square foot, but says their higher cost is balanced by their superior performance benefits.

No. 47 - 1981

No. 47 - 1981

Sparkly Restaurant Decor

Embossed copper panels, a popular material for covering interior ceilings and walls since before the turn of the century, are back in vogue as architects increasingly specify the decorative panels for both residential and commercial projects. The famed Maxwell's Plum in San Francisco is cited as just one example of upscale restaurants to feature the panels as a key design element.

No. 48 - 1981

No. 48 - 1981

Major Manufacturers Enter Solar Market

The appeal of solar power is expected to increase with the entry of the world's largest carmaker into the expanding solar collector market. Seeking new markets outside its traditional automotive business, the Harrison Radiator Division of General Motors now designs and produces all-copper solar collectors. The units, which heat a home's domestic water, will be sold through solar equipment installers nationwide.

No. 49 - 1982

No. 49 - 1982

Classical Exterior for Symphony Hall

A 14,000-sq-ft batten seam copper roof crowns the Louise M. Davies Symphony Hall in San Francisco. An informal survey of architects from New England to California shows an appreciation of copper roofing as an often less-expensive choice for quality and longevity as well as classical beauty, which, according to the Symphony Hall architect, "is so linked with the city's image and prestige, there was no way that roof could be anything but copper."

No. 50 - 1982

No. 50 - 1982

Brass Beds Make a Comeback

Proving once more that "what is old can be made new again," brass beds make an amazing comeback among American consumers. The elegant, old-fashioned beds, relegated for many years to back bedrooms, antique shops and grandmothers' attics, now compete sale-for-sale with modern wood-frame beds in showrooms and department stores. American companies that first imported brass beds to fill orders are again making their own.

Copper shingle roofing is extremely durable and attractive.

Copper shingle roofing is extremely durable and attractive.

No. 51 - 1982

No. 51 - 1982

Big Oil Rigs Rely on Copper Piping

Encrustation by marine organisms is causing oil producers to replace deteriorating steel piping on their offshore drilling rigs with longlived copper-nickel piping. Plumbing systems on the rigs are used mainly to draw in cooling water, but steel piping develops internal marine growth that impedes flow. Coppernickel is not only naturally impervious to biologic infestation, it is also highly corrosionresistant; experts predict it will find many other uses on the big rigs.

No. 52- 1982

No. 52- 1982

The 'Wright' Shingles

In homage to its iconic namesake, the Frank Lloyd Wright Foundation selects copper shingles for the 3,000 sq. ft. roof of a new home to be built in an exclusive downtown Denver neighborhood. The home's design evokes the architect's "organic" approach to residential architecture, and the copper shingles were chosen to represent the excellence and elegance for which Wright was famous.

No. 53- 1983

No. 53- 1983

Screening Out Undesirables

Biologically resistant copper-nickel screens over underwater intakes protect the nation's water supplies from invasive marine life and debris. The intakes are designed so that water flows too slowly to draw in marine organisms, but these and other unwanted materials eventually find a way in. The copper-nickel prevents organisms from attaching to the screens, and the screens are easy to remove to clear away any material that could block the intakes.

No. 54- 1983

No. 54- 1983

Resilient Automobile Radiators

The advantages of welded brass radiator tube over lock-seam tubing are so great, a new plant is built in Dearborn, Michigan, that can produce welded tubing at 600 feet per minute. Fabrication benefits include higher productivity, reduced solder use and stronger tube-to-header joints. Zinc-based solders with three times the thermal conductivity of lead-tin solders are in development to make the copper and brass radiators lighter, stronger, more efficient and potentially more economical.

No. 55- 1984

No. 55- 1984

Efficient Supermarket Refrigeration

One of the largest U.S. manufacturers of supermarket cooling equipment chooses copper for heat exchange coils and refrigerant tubing on its products. Copper coils increase the efficiency of multiple freezers and refrigerator units, enabling them to use less energy, and require less than half the maintenance of steel-coil units. A copper-coiled unit can serve up to 30 refrigeration circuits compared with a steeltube unit, which may serve only three, according to the manufacturer. Copper-tubed evaporative cooling is also becoming popular for computer-room cooling; some 6,500 pounds of copper tubing is reportedly used to cool equipment at a San Diego computer lab.

The solid brass bed is back in style-with dozens of U.S. manufacturers trying to keep up with demand.

The solid brass bed is back in style-with dozens of U.S. manufacturers trying to keep up with demand.

No. 56 - 1984

No. 56 - 1984

Medical Diagnostic Imaging

Nuclear Magnetic Resonance imaging systems have become powerful medical diagnostic tools, but they require shielding to prevent radiation from escaping and unwanted magnetic waves from entering. Rooms containing the equipment are encased with copper sheeting to protect patients and staff and to prevent stray radio frequency signals from distorting the diagnostic images. NMR systems generate magnetic fields 40,000 times stronger than the Earth's magnetic field

No.57- 1984

No.57- 1984

Keeping Shoppers Cool

Major shopping center developers, especially in Sun Belt states, are increasingly choosing copper over steel tubing for vital area-cooling systems. Based on life-cycle costs, copper proves to be less expensive because it lasts longer than steel and less maintenance is required.

No. 58 - 1985

No. 58 - 1985

No-Stick Copper

Marine use of copper alloys continues to rise due to their resistance to corrosion and biofouling. Applications include offshore oil drilling rigs, ship hulls and components, and intakes to water systems for municipalities and power plants. Because marine life does not adhere to copper, there is also less weight buildup and correspondingly less strain on structures.

No. 59 - 1985

No. 59 - 1985

Energy Saving Bronze Louvers

Operable louvers made of bronze block up to 85 percent of the sun's rays in summer and prevent heat from radiating out in winter. The louvers, which are attached to the outside of windows in a home or business, also block outside noise and can protect the windows from damage during high winds, hurricanes and hailstorms.

No. 60 - 1985

No. 60 - 1985

Shielding Lady Liberty

After standing for nearly a century in New York harbor, the Statue of Liberty is undergoing a complete renovation. Investigators find that despite continual exposure to its harsh saltwater and industrial environment, the copper cladding on the statue shows hardly any erosion. Most of the statue will remain intact, but as part of the restoration its torch and flame are to be replaced with new ones identical to the original design

This copper dome on a Cleveland medical clinic protects a nuclear imaging system from interference by stray radio frequency signals.

This copper dome on a Cleveland medical clinic protects a nuclear imaging system from interference by stray radio frequency signals.Also in this Issue:

- Four Decades of Innovation: Issues 1 - 25

- Four Decades of Innovation: Issues 26 - 60

- Four Decades of Innovation: Issues 61 - 99

- Copper Shines on Prime Time

- The History of Copper

- The Future of Copper