Copper Quality at Lower Cost

Creative architects are offering beauty and functionality to building owners at lower cost by specifying engineered copper systems for roofing and exteriors. Here are three outstanding examples.

By facing the recently completed Georgia Public Health Building with copper shingles, architect Terry Sargent has created a potential landmark.

According to Sargent, the two-story building is not only "... beautiful with an appealing texture," its 90 occupants are "ecstatic" about working in it.

The 66,000-square-foot structure also attracts the eyes of passers-by on busy Peachtree Street in a suburb of the state's capital.

The facade of copper shingles also cost less than one popular alternative, bricks. The shingles, manufactured right in Atlanta by Conklin Metal Industries, are made of 16-oz copper. Shingles, gutters and downspouts are also of copper.

Sargent, a principal in the Atlanta-based firm of Lord, Aeck & Sargent, had previously specified copper shingles on an unusually curved roof for one of the buildings at the Atlanta Zoo. Copper has another appeal to Sargent: it is environmentally benign because so much of it is recycled.

Exterior walls on the Georgia Public Health building are made up of factory-fabricated copper shingles. Besides providing a striking appearance, the shingles actually cost less than a brick wall system.

Exterior walls on the Georgia Public Health building are made up of factory-fabricated copper shingles. Besides providing a striking appearance, the shingles actually cost less than a brick wall system. The engineered copper roof on The Buttes resort in Mesa, shining brilliantly in the Arizona sun, blends well with the other construction materials.

The engineered copper roof on The Buttes resort in Mesa, shining brilliantly in the Arizona sun, blends well with the other construction materials."Copper has a special significance in Arizona because so much is mined here" That's one of the main reasons why Steven Bassett specified a copper roof for The Buttes, a 380-room resort in Mesa. Another reason he favored copper is that "... it blends so well with the building's other materials."

And the client is very pleased with the results.Bassett, a partner in the Phoenix-based architectural firm of Conoyer-Hedrick, has specified copper to clad other projects. For instance, he chose copper fascia for a high- rise condomium now under construction in Phoenix. The copper engineered system was supplied by Mesa-based Kovach, Inc., which also installed the roof on the $36 million building.

"A Best Buy"

"Based on life-cycle analysis, copper is a best buy." That's why Scott Burton recommended copper over other metal roofing to the management of the Wyeth-Ayerst-Lederle campus in Pearl River, New York. He's the property owner's project engineer for a $600,000 renovation of one of many buildings on the big campus. Most of the cost went into a new copper roof for the four-level building; the rest was for some masonry work and the tarred flat portion of the roof.

The engineered roofing was fabricated by IMETCO, Tucker, Georgia, and installed by Pfister Roofing, Fairlawn, New Jersey. Most of the 20-oz material was delivered to length. Shorter segments making up V-shaped portions of the roof (see photo) were trimmed from longer lengths. The seams on the roof are only 16 inches apart to help provide uplift resistance to meet Factory Mutual I-90 requirements.

Snow guards soldered onto the factory-fabricated copper roof segments of a 40-year-old building at the Wyeth-Ayerst-Lederle campus prevent ice and snow from sliding down on employees.

Snow guards soldered onto the factory-fabricated copper roof segments of a 40-year-old building at the Wyeth-Ayerst-Lederle campus prevent ice and snow from sliding down on employees.Because the area is subject to much snow in winter, kidney-shaped snow guards were soldered to the engineered segments on site to prevent snow and ice from sliding off and injuring people entering or leaving the premises.

The copper roofing replaced the original slate roof on the 40-year-old building, which houses both pharmaceutical research labs and some production facilities. Wyeth-Ayerst-Lederle is a division of American Home Products. The consulting engineer for the project was Raffi Abdur-Rahman, VSA & Associates,New York.

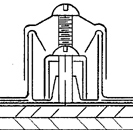

Copper batten seam detail from Overly Manufacturing.

Copper batten seam detail from Overly Manufacturing. The Edison Building in St. Louis is topped by an intricate, engineered copper roof. The manufacturer offers a 30-year warranty.

The Edison Building in St. Louis is topped by an intricate, engineered copper roof. The manufacturer offers a 30-year warranty.For a listing of copper engineered systems, see our Architecture section.

Conklin: 404/688-4510

Conoyer, Bassett: 602/381-4848

IMETCO: 770/908-1030

Kovach: 480/926-9292

Pfister: 201/791-3006

Sargent: 404/253-1435

VSA & Associates: 212/338-9661

Also in this Issue:

- Copper Quality at Lower Cost

- Energy-Saving Software

- The Advantages of "Engineered"

- Copper Key to Most-efficient Home Heating and Cooling

- Leonardo’s Bronze Horse Installed

- Copper-The Metal for Every Millennium

- Copper Spacecraft to Thrill the World