Copper on the Stove: Honoring Duparquet, Huot & Moneuse, Co.

Designed in the style of historic American Duparquet, Huot & Moneuse, Co. pots, pans and serving dishes, Duparquet Copper Cookware continues the tradition of this unique craft for new generations to enjoy.

Jim Hamann and his crew put design and craftsmanship of a unique degree into the Duparquet Copper Cookware lineup.

Jim Hamann and his crew put design and craftsmanship of a unique degree into the Duparquet Copper Cookware lineup.Photo courtesy of Duparquet Copper Cookware.

In 2008, Jim Hamann opened Duparquet Copper Cookware as a sister business to the Rhode Island-based East Coast Tinning which is housed in the same building. He re-registered the long ago abandoned trademark of Duparquet, Huot & Moneuse, Co. to refresh the honor and recognition which it actively held across the span of one century into another.

His artisan copper cooking and serving pieces are from his own drawings yet also modeled in part after those made by Duparquet, Huot & Moneuse, Co., which operated under a few different business name incarnations since the early 1850s. The company specialized in stoves and everything used to cook on them—and shut down in 1936 because of difficulty in staying afloat during the Great Depression.

Their cooking ranges were largely marketed to facilities where masses of people regularly needed to be fed, like steamships, hospitals and prisons.

“With that, they were able to sell absolutely everything else which went into a kitchen, so they were selling knives, copper pans, corkscrews, tables, sieves, and whatever else was needed,” Hamann says.

In its prime, Duparquet, Huot & Moneuse, Co. operated sales offices in Chicago, Washington, D.C. and Boston, while its manufacturing was based in the SoHo section of Manhattan.

And while the stoves are now largely gone, a good amount of the company’s copper pans have had better luck in surviving--unlike cast iron pans which were melted down to support war efforts.

“I was seeing some of the most incredible pieces coming through my hands, spectacular in quality, much different than what is made today and new, whether in France, Italy or elsewhere,” Hamann reflects about his retinning work inspiring his second business.

“You can’t find thickness like that copper and the gorgeousness of the handles and the massiveness of the rivets,” he adds. “There’s definitely a look and feel based on not only the Duparquet pieces of yesterday but the old French and English pieces.”

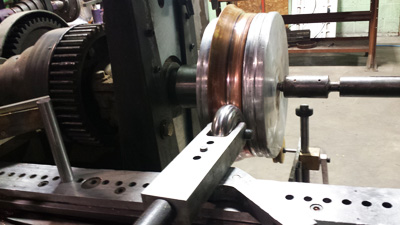

Mid-spinning of a new Duparquet copper saute pan into shape on a lathe.

Mid-spinning of a new Duparquet copper saute pan into shape on a lathe.Photo courtesy of Duparquet Copper Cookware.

Hamann notes that the majority of new, mass-produced copper pots of today are 1.5 millimeters thick to 2.5 millimeters thick, at the most, while the historic ones he’s seen were sometimes up to 3 millimeters or 4 millimeters thick and have much better efficiency of impact with even heating while preparing foods. His own usual thickness in cookware can reach about 3 millimeters thick, in certain designs. He even created a thin, flat copper heat diffuser for those who don’t have the budget for his shapely cookware but still want the heating benefits.

Hamann says that in our throw-away society of big box stores and their products so often made in China, he is glad to be proactive in making something in our country which will endure across generations.

To create their unique line of copper pots, pans and serving dishes, Hamann’s team uses a Pryibil spinning lathe and a steel lathe chuck dating back to the 1930s.

He sources his copper from Copper and Brass Sales, a division of ThyssenKrupp Materials NA, Inc. in Wallingford, Connecticut and Rotax Metals, Inc. in Brooklyn.

Orders for his pots and pans have shipped to every state in the U.S., and most of Hamann’s clientele are not executive chefs but enthusiastic home cooks.

“They love food, they love cooking at home, and the vast majority of them are not professionals,” Hamann says. “Copper cookware has longevity and character which products today don’t have.”Resources:

Also in this Issue:

- NYC Art in the Parks Brings Emerging Bronze Sculptors to the Public Eye

- Kait Rhoads: Fluidity Through Copper

- Metal Musings: Bronze Works by Richard Summons

- Copper on the Stove: Honoring Duparquet, Huot & Moneuse, Co.

- Jaume Plensa’s Newest Bronze Exhibition on View at the Galerie Lelong