The Water Studio: The Alchemy of Copper, Fire and Water

L. Avenue. Water sculpture with rain curtain in a courtyard. Ridged and smooth copper with bronze patina.

L. Avenue. Water sculpture with rain curtain in a courtyard. Ridged and smooth copper with bronze patina. Photograph courtesy of Water Studio

The delicate marriage of water and fire is one of the artistic graces that designer Sean So has mastered. For more than twenty years, he and his team at Water Studio in Culver City, CA, have been creating large-scale copper art pieces that seamlessly play off the dichotomy of the elements, bringing a touch of nature inside some of the country's most notable buildings.

The studio began as a small artistic venture by the late area artist Eric Orr. Trained under Orr, So rose to head the studio and developed its new vision, eventually becoming a pioneering member of the California art movement known as Light and Space. As his artwork become more well-known, the Water Studio grew as well, and today you can find their frameless water veils and water-feature sculptures in casinos, corporate headquarters, resorts, spas, medical facilities, and outdoor public art installations.

"In the past, it was mostly art by commission only," says So of the growth of the studio. Only within the last six years, has the Water Studio taken on more commercial projects. Now we do commercial, residential, and public art," So says.

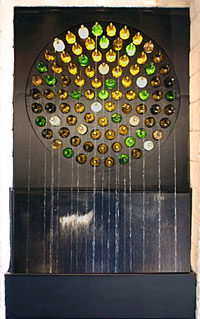

Javier's Cantina. Glass bottle water feature in a restaurant. Wine glass bottles, copper with bronze patina.

Javier's Cantina. Glass bottle water feature in a restaurant. Wine glass bottles, copper with bronze patina. Photograph courtesy of Water Studio

So's team of designers include project managers with degrees in architecture and engineering. His skilled fabricators are not only experienced craftsmen in copper, but also are versed in stonemasonry, metal finishing, welding, metal forming, and water-jet cutting.

When the Water Studio takes on a project, So works with his team to create a design that is site specific. "I try to design something that fits the space," he says. "It must work with the different architectural elements in the building. It must use materials that are consistent with other finishes. I try to listen to the architect and the client to design something that works with the flow of traffic within the space."

From this stage, the project can either go to a private contractor to build or the Water Studio is hired to do it. "We've done a lot of projects with granite and stone and other traditional building materials, such as tile and concrete. For those projects, we would design and provide construction drawings, and another contractor would actually build it," So says. But that isn't the case with copper. "You don't find people who've worked with copper in the way that we work with copper…The processes that we use are unique. We machine copper. We both solder and weld copper. It's hard to find somebody who can weld copper with the quality that we expect."

Additionally, the Water Studio's work with copper is unusual. So doesn't work with thin panels of copper or use bare copper with water flowing over it. "I stay away from that thin copper, hammered, very common look," So says. Using thicker pieces, usually 1/8 inch to 3/16 inch thick, he and his fabricators create large flat surfaces. "It's very pristine. The surfaces are very precise. You don't see any irregular movement of the surfaces." To achieve that, he says, "We try to work with copper so it has the appearance of bronze."

Working on a copper feature at Water Studio.

Working on a copper feature at Water Studio. Photograph courtesy of Water Studio

But unlike bronze and brass, copper can achieve a patina that not only is pleasant to the eye but it also enhances its ability to stand the test of time. "Almost every copper project we do has some kind of patina on it," he says. So achieves that through acid washes. "If it's a small project, we'll dip it into an acid bath. For most of the bigger projects, we'll spray it on….It's not an exact science. There are a lot of conditions--temperature, humidity, surface preparation-that vary the look. With copper patina finishes, it is not always the same. I look for the bronzy aged look, but it's not always consistent…It's a natural finish. It's going to change over time. That's one of the things I like about it."

And copper is long lasting. "One of the reasons we chose copper is that over time bronze or brass corrodes more than copper. A lot of these bigger projects that we work on, we want to make sure they last longer than our lifetime." This is particularly important when working with water running continuously over a metal surface. "It will be continuously submerged under water. Because of the corrosive metals in bronze and brass, it does corrode. With copper projects, there's some change from the patina, but there's not significant corrosion of the material itself because it's so pure."

Resources:

Also in this Issue:

- The Water Studio: The Alchemy of Copper, Fire and Water

- Ginny Ruffer: Finding Art in the Everyday

- Meet Metalsmith Henry Litchfield

- Sue Runyon Designs: Handcrafted Jewelry Inspired by Nature

- Tiffany Exhibit Makes the Only U.S. Stop in Richmond