Other Headlines

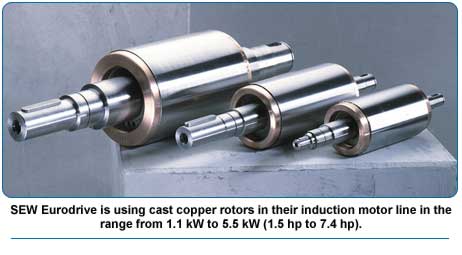

Commercial production of die-cast copper motor rotors for industrial applications has begun. SEW Eurodrive of Bruchsal, Germany, is selling a select line of its motors that capitalize on the rotors and offer price-competitive high-efficiency. It is the first company, worldwide, to bring the technology to market.

According to Martin Doppelbauer, SEW manager of motor development and design, die-cast copper has replaced aluminum in the company's line of high-efficiency gear motors. In a recent interview with Update, he explained why the technology was especially attractive for this particular type of motor. "All the well-known technologies for improvement of energy efficiency of electric motors involve a significant enlargement of the motor. The motors grow longer and, in many cases, also increase in diameter," he said. "For us this represented a major disadvantage because, with gear motors, the combination between a motor of certain power and a gearbox of certain torque is critical for the products to work." He explained that since traditional high-efficiency motors are larger than standard motors, they would not be able to 'fit' with their corresponding gearboxes. "We were looking for a solution to increase efficiency substantially without having to enlarge the motors. Copper rotor technology gives us that advantage," he said.

SEW trials consistently revealed an increase of efficiency of between 1 percent and 3 percent. "Although this might not sound like much at first, one should remember that electric motors are very mature products. For products with an age of over a hundred years, the improvements are certainly impressive," Doppelbauer said. He attributed the increase to many different factors. He cited a total reduction of losses of 10-15 percent versus aluminum motor rotors. SEW trials also revealed a reduction in stray load losses of 20-50 percent.

Stray Load Losses

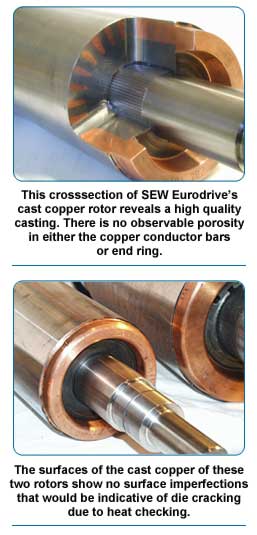

Stray load losses are the accumulation of several types of losses. The consistency of the air gap between the stator and the rotor, as well as rotor balance can affect stray load losses. Likewise, consistency in the conductivity of the rotor conduction bars is critical to proper magnetic induction. Porosity or nonmetallic inclusions in cast rotor bars can result in variations in the rotor bar cross-sectional area and, therefore, affect uniform current distribution, which results in variations in the magnetic field in the air gap. This increase in stray load losses via inconsistent magnetic flux density reduces overall efficiency. Prototype production tests made it clear that die-cast copper rotors contribute to overall motor efficiency because they can be manufactured with a consistency not normally achieved in typical motor production.

Furthermore, U.S. motor manufacturers use a dynamometer efficiency test as per IEEE Standard 112, Test Method B, as required by the National Electrical Manufacturers Association (NEMA) and the Energy Policy Act of 1992 (EPAct). European motor manufacturers use the IEC 34-2 test method. Rather than performing an actual test, the IEC method assumes a fixed percentage as stray load losses. The IEEE test method is a true watts-in versus watts-out efficiency test that segregates the energy losses into five categories: iron core losses, stator resistance, rotor resistance, windage and friction, and stray load losses. The first four losses are measured directly, and the remainder is in the "stray load" category. Stray load losses are reduced by the copper rotor; therefore, it is important to determine this loss rather than assume a value for it. For example, SEW Eurodrive's motors are actually more efficient than the nameplate implies, having as much as a 0.5% increase in efficiency, because the IEC test method assumes stray load losses are higher than they actually are measured to be. This discrepancy between the results of the two test methods makes a very strong and convincing case for measuring all five categories of losses.

Doppelbauer said that he foresees numerous applications that could benefit from the groundbreaking technology. He explained that one of the most impressive advantages is the impact the technology has on the ultimate cost of ownership for the end user, which derive from increased efficiency as well as a possibly lower purchase price. "We believe that copper technology may have a positive impact on manufacturing costs in the future because it will be possible to reduce the size of the motor. Motor size is a major cost driver. If we could use copper technology to reduce the size of today's motors, we believe there would be a chance for significant price reduction," Doppelbauer explained.

Doppelbauer said that he foresees numerous applications that could benefit from the groundbreaking technology. He explained that one of the most impressive advantages is the impact the technology has on the ultimate cost of ownership for the end user, which derive from increased efficiency as well as a possibly lower purchase price. "We believe that copper technology may have a positive impact on manufacturing costs in the future because it will be possible to reduce the size of the motor. Motor size is a major cost driver. If we could use copper technology to reduce the size of today's motors, we believe there would be a chance for significant price reduction," Doppelbauer explained.

"One might believe that copper motor rotors suffer from the increased weight of copper versus aluminum. However, this is not the case, since motors with copper rotors can reach the same efficiency and the same output power with substantially smaller moving parts than aluminum motors," he said. "We found the general rule was that, when comparing on equal grounds, copper motor rotors have more or less the same moment of inertia as their aluminum counterparts. Even better: since the nominal slip of copper rotor motors is smaller than that of aluminum motors (i.e., the motor runs faster), the usability for frequency-converter operation is improved. Especially at low speeds and frequencies, the motor with a copper rotor reacts with much more stability to changing loads."

Slip

Slip is the difference between the synchronous rpm of the field rotation at 60 Hz (or 50 Hz elsewhere in the world) and the full-load rpm of the rotor and shaft assembly. All other factors being equal, this difference is what creates the torque to rotate the load. The copper rotors achieve this torque point with less slip for a higher measured rpm. This helps creates what is called in the industry a "stiff" motor or one that does not slow down much under load. This implies a very responsive motor on variable frequency drives if high-performance servo-like speed changes are desired.

Doppelbauer said that, so far, customer reaction to cast copper technology has been very positive. However the demand for true high-efficiency motors in Europe is generally low. "We are facing the same problem as all of our competitors: the potential end users of high-efficiency motors purchase machinery from original equipment manufacturers and concentrate their negotiations on reducing purchase prices. The idea of long-term energy costs versus one-time purchasing costs is still not popular. Some countries give tax incentives for high-efficiency motors or impose regulations. The situation, of course, differs from country to country."

Within the motor industry, Doppelbauer hasn't seen much reaction to the announcement of commercialization. "Our competitors seem to be surprised somebody is now accepting the challenge and are waiting to see if the new technology will really work out as promised."

"SEW is a privately owned company and is willing to take a risk if there is a chance of succeeding," Doppelbauer said. "SEW has always concentrated on opening new fields of activity. Consequently, while competitors have lowered their product development efforts, SEW has constantly improved its research and development budget over the years." Today SEW employs more than 300 people in the research and development division, with more than 50 dedicated to the development of electric motors. Doppelbauer believes this is the largest motor-specific research and development group in the motor industry.

The innovative culture at SEW allowed the company to introduce cast copper rotor technology to its product line less than two years after their research project began. If cast copper rotor technology delivers on its promise, Doppelbauer believes SEW will have gained a head start in the field of induction motors by at least two years against their competitors. SEW Eurodrive manufactures integrated motors and drive technology. It has international sales of approximately $1 billion (US).