The R&D effort led by CDA has demonstrated that the die-casting of copper motor rotors can be a viable industrial practice from both technical and economic standpoints. Numerous technical obstacles have been overcome along the way, not the least of which was die checking, solved through a method (now patented by CDA) that ensures long die life. Problems with porosity have also been addressed, first through computer-aided modeling and then by tweaking those mathematical results in actual casting practice. Finally, problems with variable electrical conductivity were successfully resolved by carefully protecting the molten charge from oxidation.

Most of the practical elements of the program were undertaken at Formcast Development Inc., Denver, and subsequently at V-Forge, Inc., Englewood, both in Colorado. Casting was performed on a 750-ton (660-tonne) Bühler horizontal, real-time, computer shot-controlled die-casting machine. The development work, therefore, deliberately simulated what would become normal industrial production.

But "horizontal" die-casting machines, those in which the shot sleeve, plunger and principal axis of the casting are aligned horizontally, are not the only style of machines used in the production of motor rotors. In fact, in the USA, the majority of motor rotors - certainly in larger-than-fractional-horsepower sizes - are cast in "vertical" machines similar to the one shown in Figure 1 - and for good reasons, which we'll address in a moment.

THT Presses, Dayton, Ohio, is the leading manufacturer of vertical die-casting machines in the world. A 30-year-old company, THT has been manufacturing vertical machines since 1977. Since the early 1990s, the company has pursued the development of copper motor rotor die-casting technology independent of the CDA-led consortium. The company was associated with the consortium shortly after it was organized in the 1990s, but, for a number of technical and commercial reasons, the company soon opted to undertake its own development program.

In THT's version of the vertical method, the shot sleeve and piston are located directly beneath the die, Figure 1. In preparation for casting, the lower die assembly is withdrawn sideways, allowing the molten charge to be poured into the exposed shot-sleeve cavity. The lower die is then shuttled back into position under the upper die, and the entire assembly is sealed by means of a multi-ton clamping force applied from above.

The piston is then raised, directing molten metal upward through multiple orifices (gates) in the gate plate and into the die cavity. Piston travel is computer-controlled to minimize turbulence, as molten metal flows into the die. In some respects, the vertical die-casting process closely resembles low-pressure die- or permanent-mold casting, except that casting pressures are considerably higher.

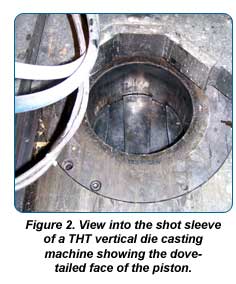

After the shot is completed, the clamping force is relieved, and the piston is lowered. At this point, the solidified biscuit is locked to the piston by dovetails on the piston's face, Figure 2. As the piston recedes, the biscuit breaks cleanly away from the casting, thereby greatly simplifying post-casting clean-up operations. The lower die assembly is then withdrawn sideways, and the piston is raised to expose the dovetails. This allows the biscuit to be slid off for recycling. The piston is then once again withdrawn vertically, readying the machine for the next shot.

Inert Advantages

"We like to think of our process as a bridge between low-pressure, or gravity die casting, and the conventional high-pressure method," says John Lawson, technical and business director for THT's motor division. "We realized that our vertical casting method offers a number of advantages for axially symmetric products like motor rotors," says Lawson. "Our founder and president at the time, Ted Thieman, had years of experience casting aluminum rotors our way, and he had his own ideas about how to make the process work with copper."

According to Lawson, the most important technical advantages of the vertical process stem from the way liquid metal flows into the die. Most important is that, rather than making several 90-degree turns as it does during horizontal casting, metal flows essentially in one direction (up) from the shot-sleeve cavity to the die. Lawson believes this feature, plus the relatively short travel distance involved and the multiple gates arranged completely around the lower end ring, sharply reduce the chance of developing porosity in the casting.

Other advantages of vertical casting cited by Lawson include smaller machine footprints, lower clamping pressures and much faster die change-outs compared with equivalent-sized horizontal equipment.

What about die life? CDA's research found that achieving die life in the thousands of cycles requires the use of nickel-based superalloys in critical die areas, along with preheating the entire die assembly to temperatures around 1200°F (650°C).

However, the simplified arrangement of components in the vertical process does away with the need for some of the superalloy inserts used by CDA, explains Rick Kamm, THT's cofounder, who heads new technology development for THT Presses. He says, "Most of the damage we saw was in the gates, which are relatively thin and crack readily. We initially got around that problem by simply replacing the gate plate periodically. After awhile, we began making the gates as inserts to the gate plate, which works just as well and cost less."

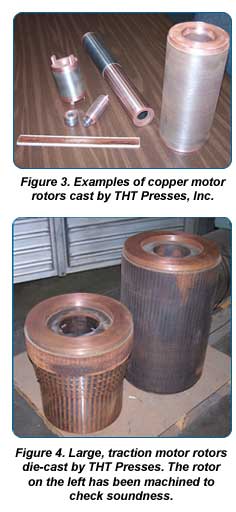

Figures 3 and 4 show examples of copper rotors cast by THT on one of its machines. The castings are of commercial designs and were made for evaluation by several of the company's customers. The large rotors shown in Figure 4 (one has been partially machined to check it for soundness) are prototypes for traction motors. They contain more than 600 lb (270 kg) of copper apiece.

THT also casts rotors in aluminum bronze, a novel development that appears at first glance to fly in the face of conventional wisdom. Ordinarily, lower conductivity (as with aluminum bronze and with aluminum, itself, when compared with copper) is undesirable, since it increases rotor losses and lowers motor efficiency. Here, the aluminum bronze's 18% IACS conductivity is used to increase the motors' slip, thereby greatly increasing starting torque, which is a design requirement for these particular motors. A number of commercial aluminum-alloy rotors also offer this feature, but THT's customer selected the bronze instead, based on its superior mechanical properties.

Earlier Update articles have described how companies around the world are now producing copper motor rotors on a commercial scale. Some, like FAVI, achieved success after years of doing their own R&D. For others, like the several Indian manufacturers featured in the October 2004 issue of Update, success came as result of applying know-how gained in CDA's development program. In THT Presses, however, we see a born-in-the-USA company that combined its own extensive experience in motor casting with a good measure of out-of-the-box ingenuity to accomplish the same results. It's results that count in the end, and congratulations are definitely in order!