Gaining electrical efficiency levels higher than those obtainable in aluminum-cage premium motors has been a leading motivation - maybe the principal driving force - behind development of copper-rotor motors by the Copper Development Association. Happily, it worked. We now know copper-rotor motors designed specifically for high efficiency do indeed outperform their conventional counterparts, usually by between one and several percentage points, a very significant improvement. Of course, that high level of efficiency can be traded off against size and weight reduction and/or higher power rating, but it is the ability to consume less energy for a given horsepower output (and thereby reduce life-cycle costs) that usually certifies the copper motors' commercial value.

However, efficiency isn't always the single most important operating parameter, particularly in motors other than standard, 60-Hz, NEMA designs. Here, we're talking about specialty motors, those designed to meet unique or particularly demanding requirements. Those requirements can include speeds in the tens of thousands of rpms at high power ratings, virtually silent operation, dimensional stability measured in angstroms and power densities (hp per pound or per volume) not attainable in even the finest conventional machines. This is edge-of-the-envelope electric motor design, and, not surprisingly, copper rotors are playing a major role.

Many Options

While tweaking the rotor is only one of many options open to motor designers bent on achieving higher performance, one innovative manufacturer has found that die-cast copper rotors provide greater design flexibility as well as the ability to make cost-effective improvements in manufacturing.

The company is Welco Technologies, a more than 110-year-old concern headquartered in Milford, Ohio, with manufacturing and R&D facilities in Maysville, Kentucky. Welco has gained an enviable reputation for providing unique motor solutions to customers in such diverse industries as glass and polymer fiber production, machine tooling, automotive (and other) test stands, medical imaging, commercial aircraft, and defense and aerospace. All Welco Technology motors are "special."

"We like to call what we do solutioneering, or solutions plus pioneering," says Jim Kokenge, Welco's director of business development. "People come to us because we have the experience and capability to design and manufacture motors for the most difficult applications, often when others have failed or when major motor suppliers won't even try. We've created literally thousands of specially designed motors that you could never buy off the shelf. Although we do a lot of repeat business, our orders might involve as few as one motor or as 'many' as a dozen a month. These are not prototypes; they're tailor-made machines made in limited quantities for very specific applications."

Forget About Aluminum

So far, Welco has only used die-cast copper rotors in a handful of its motors. One reason: CDA's production-scale die-casting technology is relatively new, and the rotors simply weren't widely available in the past. Another factor is that the rotors aren't always called for, as in Welco's line of permanent magnet motors, whose rotors contain no copper whatsoever. There's also a cost factor we'll talk about later. But, according to Shailesh Kapadia, Welco's vice president of technology and its principal motor designer, die-cast copper rotors offer important advantages, both in performance and manufacturability. This is particularly the case in the company's AC induction motors, most of which are based on copper.

"We use copper rotor bars in most of our AC motors," says Kapadia, "because in those cases, you just can't meet the specs without it. However, until recently, most of our rotors were hand-fabricated, and some still are. Today, we can show you examples of fabricated motors in which we would definitely have used die-cast copper rotors if they had been available at the time, and we can also show you cases where only by using die-cast copper rotors could we meet the customer's requirements.

To understand Kapadia's points, we have to look at a few of the ways Welco uses copper. Figure 1 shows the die-cast copper rotor from a recent design. Notice that the laminations are skewed, an important point we'll get to in a moment. Here, the customer needed high power in a small package. What he got from Welco included a rotor not much larger than a Wisconsin bratwurst, yet the motor in which it spins turns out an astounding 8 hp. In another instance, Welco supplied motors for a state-of-the-art commercial airliner that pack 14 hp into only 12 lb of active components (stator and rotor), a job in which Welco was challenged to take out one-half ounce of weight…and did.

Welco routinely doubles the horsepower in a given (conventional) volume. "We make a fabricated motor in which we put 100 hp in a NEMA 180 frame" says Kapadia "Of course, it's not just the copper, but other design features, as well, that make this possible, But, at 30,000 rpm, you can forget about aluminum, and, at 100 hp, your primary problem is how are you going to cool that thing? Die-cast copper is one part of the answer."

In still another application, a customer asked for, and got, a 250-hp, 60-Hz motor running at 3,600 rpm with 97.13% efficiency. The NEMA Premium efficiency for this type of motor is 96.5%. According to Kapadia, a die-cast copper rotor would have improved efficiency even more. "And," he recalls, "you could put your hand on the motor and not tell it's running at 3,600 rpm and 250 hp."

Welco also designed and made a 211-hp, NEMA 320-frame motor that could accelerate from zero to 8,000 rpm, stop, and reverse itself to the same speed in just one second. "My jaw dropped when I saw it," says the obviously proud motor designer. "That particular motor had a fabricated copper rotor, but it's one of those which, if we had to do it today, would be a good candidate for die-cast copper."

Copper Reduces Noise and Weight

Why die-cast copper? Kapadia explains that "In these lightweight, high-speed, low-noise, and/or variable frequency motors, you have to design-in rigidity because you can run into dynamic effects. In this regard, one of the advantages we see with die-cast rotors has to do with the rotor bars themselves. In these motors, we have to skew either the rotor bars or the stator to reduce noise. That's especially important in 60-Hz submarine motors where so-called structure-borne noise can produce an audio signature that an enemy can identify. Sometimes we skew the stator, but that makes it difficult and expensive to wind. On the other hand, if we skew the rotor bars we face the problem of fitting the bars through the slots. If there's an error in just one slot position, it accumulates, and soon the bars won't get through the stack. You can reduce the bars' thickness - and we can do that - but then we reduce current-carrying capacity and, consequently, efficiency, and we also have a loose fit that's going to cause vibration. We can work around the vibration problem with vacuum pressure impregnation (VPI), but that's a secondary operation and costs money. The better solution is to fill the slots entirely with cast copper, and that's what we've begun to do in some cases. Die-casting the conductor bars actually solves both problems - larger bar size for higher efficiency and rigidity for cost-effective noise reduction - plus it simplifies manufacturing."

Many of Welco's high-power-density motors are used in aircraft and aerospace applications, where light weight is an important design criterion ( Figure 2). These motors typically operate at 400 Hz and have at least 12 poles. Because almost all of the magnetic "action" takes place in the air gap (which can be as narrow as 0.006 in in a 36-pole machine) and the nearby lamination steel. The rest of the steel - the part away from the slots and toward the shaft - is non-contributing, magnetically. Large holes are therefore cut in those areas, taking out a lot of weight ( Figure 3).

"For example," explains Kapadia," a 2-pole, 60-Hz motor runs at 3,600 rpm; a 12-pole machine operating at 400 Hz runs at 4,000 rpm. That's pretty comparable, but the 12-pole motor weighs a lot less. Die-cast copper rotors can help cut the weight even further, and by allowing us to reduce the rotor diameter for a given peripheral speed, i.e., running at a higher rotational speed, we can pack equivalent power into a smaller package.

Another advantage the Welco engineer sees is that copper is stronger and more rigid than aluminum. "When you have a rotor spinning at 20,000 or 30,000 rpm," he says, "you need all the strength and stiffness you can get. We tried pure aluminum, which was too weak, so next we tried a dilute silicon alloy, but its conductivity was only 27% IACS and I2R losses caused an unacceptable temperature rise. In the end, copper gave us the strength, rigidity and conductivity we needed."

Improved Manufacturability with Copper

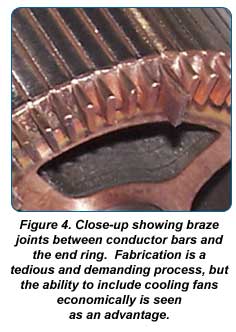

And finally, there's the matter of manufacturability. Figure 3 shows a current-production, fabricated Welco copper rotor. The large lightening holes in the laminations are visible through the end ring. All Welco motors of this and similar types are hand-fabricated. One of the most critical operations is that of brazing the conductor bars to the end rings. The close-up photograph, in Figure 4, shows a portion of the brazed joints, with (in this case) the rectangular conductor bars fitted into slots in the ring. Note that every ninth bar is longer than the others. The longer bars act as fan blades to circulate cooling air. They also provide convenient places to trim material for balancing.

The braze joints must be virtually perfect in high-speed motors like this, placing considerable demand on the skill of the craftsmen and -women who assemble the rotors. But testing the physical integrity of braze joints is difficult, and even a small physical defect, one that nonetheless permits electrical contact, would eventually lead to catastrophic failure when the motor goes through thermal cycling in service. Die casting the rotor eliminates this potential problem. It also simplifies the manufacturing process and eliminates much of the hand labor required for assembly. Finally, die casting cost-effectively increases design flexibility in that it economically permits the use of complex-shaped conductor bars. Fabricated bars with complex profiles are expensive; as castings, the shapes are essentially free.

Two Challenges

At this point, Shailesh issues two challenges to the CDA-led consortium that developed the die-cast copper rotor. First is the question of die costs. "We produce these motors in relatively small quantities," he says, "and while we see numerous advantages to using die-cast rotors in place of fabricated ones, the cost of the casting dies, amortized over only a few dozen motors, can be problematic. In particular, we'd often like to include cooling fans in the end rings. This is easy and cheap to do in a fabricated motor, but including complex shapes like fins in a die-casting die makes its cost prohibitive. We need a way to do that in a way that our customers can afford.

"Second, we sometimes make motors with two squirrel cages, one (the running cage) in high-conductivity copper and one (the starting cage) in a copper alloy with lower conductivity. We'd like a process to cast the two metals simultaneously, and maybe even cast two separate sets of end rings for the same rotor." That sounds a bit outlandish, but bear in mind that the request comes from a company whose outside-the-box designs routinely meet some very unorthodox specifications. It should also be noted that Welco Technologies does not currently cast its own copper rotors, preferring to purchase them from a few suppliers who can meet their stringent quality requirements.

More to Come

Welco's customers in the defense and aerospace industries normally don't flinch at the high cost the hand-built motors command. Commercial and industrial customers are another matter, but Jim Kokenge has two convincing arguments to justify his gilt-edged price list. "It is the combination of performance, reliability and efficiency that makes these high-end motors worth their cost," he says. "For some of our customers, a failed motor would easily result in thousands of dollars worth of product going down the drain in a matter of minutes. People pay us to design and build reliability into our motors so that doesn't happen. We also know our motors don't compete with mass-produced products on a purchase-price basis, but their high efficiency helps make them cost-effective on a life-cycle basis. It's fair to say that we'll be incorporating die-cast copper rotors in more of our future designs. It just makes sense."