Press-connect joining of copper and copper alloy tube is fast, economical, and, most importantly, it requires no heat or open flame unlike soldering or brazing.

The press-connect joining method (sometimes called press-fit) was patented in Europe in the late 1950s and continues to be used successfully there. The method and associated fittings and tools were introduced in the United States in the late 1990s. Since then, there has been growing acceptance, and those using the method experience excellent results.

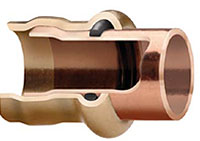

Press-connect joining takes advantage of copper's excellent malleability and its proven increased strength when cold worked. The joints rely on the sealing capability of a special fitting that contains an elastomeric gasket or seal (such as EPDM) (Figure 11.1) and the proper use of an approved pressing tool and jaws (Figure 11.2). Typical ranges of pressure-temperature ratings for these no-flame joints are found in Table 14.4b. Several manufacturers offer full product lines of press-connect fittings, valves and specialty items (Figure 11.3).

Figure 11.1. Press-connect fitting with elastomeric gasket

Figure 11.1. Press-connect fitting with elastomeric gasket Figure 11.3. Sample fittings and valves available

Figure 11.3. Sample fittings and valves available