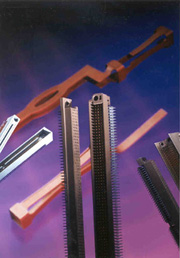

Photo ©1998 AMP INC.

Photo ©1998 AMP INC.Alloys with higher conductivity almost always have lower strength. The addition of alloying elements to strengthen a metal tends to lower its conductivity. Recall that brasses with higher zinc content have lower conductivity.

In general, the higher the strength, the lower the conductivity. But there are exceptions. Several of the highest strength alloys have almost half the conductivity of pure copper. These metals provide properties that maximize the strength/conductivity solution. The physical reason for this divergence from the general rule is that the alloying elements added for strengthening are tied-up in precipitate particles leaving very little in the copper matrix. This deficiency of alloying elements in the matrix permits the electrons to flow freely.

Connector alloys with a wide diversity of conductivity are readily available. A study of the combinations of strength and conductivity possessed by several metals will usually lead to a selection for a particular application. As often happens, the alloys which provide superior combinations of strength and conductivity also tend to have higher costs due to the alloying elements and the additional costs of special process steps such as precipitation hardening. The designer must make selections which will cost-effectively provide the required properties.