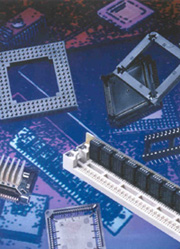

Photo ©1998 AMP INC.

Photo ©1998 AMP INC.Obtaining a requisite spring contact force from copper alloy strip stampings is an important priority for the successful designer of connectors. Insufficient contact force can cause an otherwise clever design to fail during initial evaluation, or worse, prior to expected design life. Contact force requirements are as varied as connector designs. They range from 0.03 to 10N, depending on the application and space available . The criterion that determines if a metal can provide the necessary contact force is "strength".

Basic "Strength of Materials" equations for beams, readily found in numerous engineering handbooks and texts, relate contact force to the stress in the spring member (caused by deflection). Contact force is directly proportional to the stress in the beam. The selection of alloys that allow 10, 20, or 30% more stress than other metals, gives that same percentage increase in contact force. Higher stresses are obtained by using alloys that have higher yield strength (when the yield strength is exceeded, the spring takes a permanent set and won't spring back to its original position). Thus, the yield strength of candidate alloys is an important selection criterion. Alloys with higher yield strengths can provide higher contact forces.

Producers manufacture alloys in specific tempers and supply data sheets which include the relevant material properties, especially yield strength (usually at 0.2% offset strain) and tensile strength.