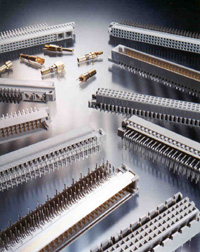

Photo ©1998 AMP INC.

Photo ©1998 AMP INC.The concepts, methods, and analyses in this design guide are intended to enable the selection of copper alloy strip that will provide the mechanical and physical properties necessary to meet initial connector requirements. They should assist in obtaining metal strip that will form the designed part without failure, guide the selection of alloys that have sufficient conductivity, and enable selection of alloys that can provide required contact forces. The metals selected can be manufactured into connectors that can be immediately tested to see if they meet initial design requirements. It is recognized that there are design requirements that cannot be immediately tested. But rather, the necessary tests may take months or even years. For example, exposures to elevated temperatures decrease the contact force over time through a mechanism known as stress relaxation, a metallurgical process. An example of a time-dependent chemical process is oxidation. When exposed to an oxidizing atmosphere, the resistance of a contact may, over time, rise to unacceptable levels. Topics in the next section in this guide address the manner in which various copper alloy strip metals can help the designer to manage these concerns.