Copper Critical in Making of Pasta

Daniel Maldari, third-generation maker of pasta dies, checking some of the firm's output. The object in his hand is a brass and Teflon insert that fits inside one of a die's many holes.

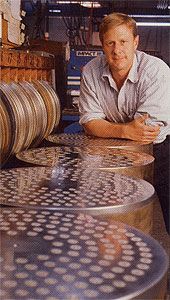

Daniel Maldari, third-generation maker of pasta dies, checking some of the firm's output. The object in his hand is a brass and Teflon insert that fits inside one of a die's many holes.Image courtesy of Danille A. Swick.

Next time you enjoy a plate of pasta, give copper some of the credit.

Most of the pasta made in the United States and in much of the rest of the world is extruded through dies made of bronze, according to Daniel Maldari. He's a third-generation maker of pasta dies with D. Maldari & Sons, Inc., Brooklyn, New York. The firm was founded by his grandfather in 1903.

Up until about 50 years ago, pasta dies were usually made of solid copper. Then manganese bronze took over. Subsequently even stronger aluminum bronze became the material of choice, according to Rob Pearson, manager, technical services, Ampco Metal Inc., Milwaukee. Ampco supplies the alloys in sand-cast form to the diemakers. Pearson said that pasta dies are made from two different alloys. One is 86 percent copper, 10.5 percent aluminum and 3.5 percent iron (C95400). The other alloy contains 80 percent copper, 10 percent aluminum and 5 percent each of nickel and iron (C95500).

Besides strength, these alloys are also more resistant than prior materials to the caustic liquid used to clean the holes in the dies at the end of each day. However, these alloys are not easy to drill. According to Pearson, the alloys are rated at 35 for drillability compared to free-cutting brass at 100. Some dies are made of stainless steel, Pearson noted. However, stainless is even tougher to machine than bronze. To make macaroni, tiny round inserts of stainless steel are mounted in the die channels.

Pasta die being milled at D. Maldari & Sons.

Pasta die being milled at D. Maldari & Sons.Image courtesy of Danille A. Swick.

Maldari claims his firm is the dominant manufacturer of pasta dies in the United States. They are also shipped overseas. As he put it, "Pasta is popular all over the world."

Maldari: 718/499-3555

Ampco: 414/645-3750

Also in this Issue:

- McDonald's Chooses Environmentally Friendly Copper

- Frank Lloyd Wright Gas Station

- Copper Sprinklers Rise to Meet Phoenix's Need

- Holy Toledo! Copper Graces both Old and New

- Copper Critical in Making of Pasta

- Saxophone Sales Swell Since Election

- "Classic" Copper for Weathervanes