Fatigue strength is of importance whenever a high number of deflections occur over the life of the component. Contact springs (or other stressed components) can fail during service when the metal is deflected and released a high number of times-even though the metal is not highly stressed. This phenomenon is called "metal fatigue." A fatigue failure is one in which the metal fractures because it is subjected to a high number of cycles at a stress below the metal's yield strength. Fatigue occurs because micro cracks develop on the metals surface when it is cyclically stressed. With repeated bending these cracks propagate through the metal thickness to a point where the remaining sound structure fails by ordinary rupture (because the load can no longer be supported).

Alloys are tested for fatigue strength by clamping one end of a tapered specimen in a fixture and repetitively deflecting the other end, first in one direction and then in the other, by the same amount. The test specimen is tapered so that stress is invariant along the beam length. This type of flexure is called reversed bending. [Fatigue tests are sometimes made with the specimen deflected in only one direction.] The deflection is calculated (from standard beam equations) so that a given amount of stress is developed in the metal. The highest stress that can be applied for a certain number of cycles without fracture is the fatigue strength. The standard fatigue strength for copper alloys is that reported for 100,000,000 cycles. At stresses above this fatigue strength, fewer cycles can be accomplished before failure; at lower stresses, the metal will withstand more cycles before failure.

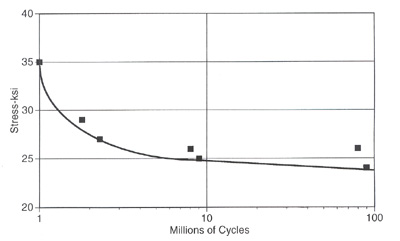

This relationship of maximum stress to number of cycles before failure is shown in the figure below. Because it relates Stress to Number of cycles it is called an S-N curve. The fatigue strength as measured by this test is 24 ksi.

Figure 3. S-N Curve for Hard Temper Cartridge Brass

Figure 3. S-N Curve for Hard Temper Cartridge BrassFatigue strength is as important to the designer of parts with high deflection cycles as yield strengths is to the designer who must obtain requisite contact forces. Different alloys and tempers provide the designer different yield strengths to obtain those contact forces. The designer of parts subject to fatigue failure can similarly select from different alloys and tempers to obtain the requisite fatigue strength to ensure long term performance.