Copper Dominates Power Generation

Generating all the alternating current on which our way of life depends is just one more application in which copper reigns unchallenged. Even in the generation of low-power direct current by batteries, copper plays a role and a growing one in some of the big, rechargeable batteries now under development. And even when fuel cells enter the market, perhaps in the next few years, copper will still be essential to distribute electrical energy with the most efficiency.

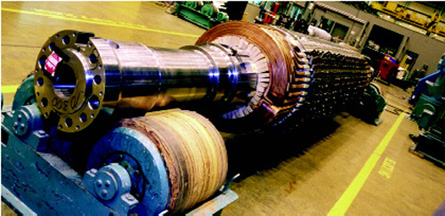

The largest generator made by Siemens Westinghouse Power Company, Orlando, Florida, contains 40,000 pounds of high-conductivity coppers (C10200, C10700, C11000 and C11600). Siemens delivers more than 100 such generators each year, producing up to a 1,000 MW each.

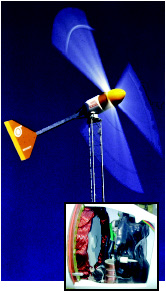

The largest generator made by Siemens Westinghouse Power Company, Orlando, Florida, contains 40,000 pounds of high-conductivity coppers (C10200, C10700, C11000 and C11600). Siemens delivers more than 100 such generators each year, producing up to a 1,000 MW each.Copper is king in all sizes of generators—from the huge ones driven by steam or waterpower, containing as much as 20 tons of the high conductivity metal, to large windmills, containing several thousand pounds, and down to small, wind-driven generators, containing only a few pounds, located far from power grids. In fact, there's even more copper in the power cables needed to connect wind turbines than in the generators themselves,according to a spokesperson for Enron Wind Corporation, Tehachapi, California (to be acquired by General Electric).

Using copper in generators is not only highly efficient but environmentally sound. When the generators are finally retired, usually not before decades of trouble-free service, all the copper in them is recycled.

Rendering of one of the 170 giant windmills planned for installation on shallow Horseshoe Shoals five miles south of Cape Cod. The will have a peak capacity of 420 MW, constituting the largest windmill farm in the USA.

Rendering of one of the 170 giant windmills planned for installation on shallow Horseshoe Shoals five miles south of Cape Cod. The will have a peak capacity of 420 MW, constituting the largest windmill farm in the USA.According to the American Wind Energy Association (AWEA), Washington, D.C., wind power is the fastest growing medium for power generation worldwide There are three important reasons for its popularity:

- It causes no air pollution.

- It takes much less time to install windmills than a conventional or nuclear power plant, important in the many regions plagued by insufficient generating capacity.

- It reduces dependence on imported fuels from sometimes unreliable sources.

The United States, which generates more than 5,000 megawatts from windmills, is second behind Germany, the world leader in wind-based power generation. Most of the U.S. windmill farms are in the western and middle-western states, but the largest American farm is now contemplated for the windy shoals five miles south of Cape Cod. If completed as planned in 2005 (there’s local opposition), its 170 giant mills would have a peak capacity of 420 MW, which would be enough to supply 8% of the population of Massachusetts.

According to Brian Braginton-Smith of Cape Wind Associates, Boston, promoters of the offshore project, there’s a big market developing for submarine power cable to deliver the power ashore. He expects more offshore generation projects in the USA and, especially, in Europe where there’s a shortage of available windy coastline. He claims that within a few years, the cost of wind-generated power will drop below that of conventionally generated power in Europe as the cost of fossil fuels rises and wind-turbine technology improves.

AWEA: 202-383-2500

Bergey: 405-364-4212

Cape Wind Associates: 617-904-3100

Enron Wind Corp.

Siemens: 407-736-2000

Also in this Issue:

- Copper Dominates Power Generation

- Treading on History

- Copper Vital in Oceanographic Research

- Copper Powers "New Generation" Trolleys