Copper Shines in Radiant Heating

Avoid Disasters with Copper

Don't let recently reported disasters involving radiant heating in Colorado dissuade you from taking advantage of this comfortable method of heating, especially if the system is made entirely of copper. The home-damaging floods, publicized nationally, involved the failure of rubber-hose tubing. The product of a leading polymer producer, the hose is no longer used in radiant heating for good reason.

According to Mo Siegel, founder and chairman of Celestial Seasonings, Inc., Boulder, Colorado, the hose "...blackened and split" in many million-dollar homes. One of those afflicted is that of former Vice President Dan Quayle.

Siegel, who couldn't sell his own home once prospective buyers found out that rubber hose was used, has investigated many failed installations. He reports that in some instances, families had to move out for months while the defective hose was removed and replaced at great cost. To avoid any future disaster, Siegel has had his radiant-heating system deactivated and replaced with baseboard heating (this was much less costly than ripping up flooring to remove and replace the rubber hose). To guarantee the reliability and life of the new system, Siegel made sure all his new plumbing was copper!For indoor comfort, there's nothing like radiant heating, which is increasingly popular for homes and commercial buildings. On the exterior, it is excellent for snow melting, especially on sloping driveways. And for reliability in radiant heating systems, there's nothing like copper tubing, which experts rate superior to its major competitor, cross-linked polyethylene (PEX).

Bob Geegan, a mechanical contractor who has been installing radiant heating for 30 years, reports that some of his very first installations are still as efficient and reliable as the day they began operating. He does not install any PEX, which he rates inferior to copper in several ways, such as much lower heat transfer and not having passed the test of time. Geegan also disputes the claim by advocates of PEX that it is easier to install than copper tubing and that the alkali in the concrete laid over the copper tubing corrodes it, which is contrary to scientific fact.

In the Chicago area, his 30-employee firm, Geegan Heating, installs some 150,000 feet of 5/8-inch OD annealed copper tubing each year to provide under-floor radiant heating, mostly in low-rise condos. Geegan also relies on the longevity of copper systems for outdoor installations to melt snow on sloping driveways (see illustration below), sidewalks and pedestrian areas.

Another expert, Tom Marvin, a veteran builder in Kirkland, Washington, a suburb of Seattle, insists that copper tubing is quite easy to install. He also reports that PEX costs more than copper tubing in his area. And, according to Marvin, some installations of PEX tubing have developed disastrous leaks.

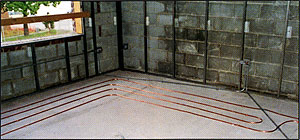

An array of copper tubing for under-floor radiant heating before pouring the concrete flooring. This installation in a Chicago area home was by Geegan Heating.

An array of copper tubing for under-floor radiant heating before pouring the concrete flooring. This installation in a Chicago area home was by Geegan Heating.In the Northwest, domestic water heaters can provide enough heat to operate under-floor radiant heating systems, says Marvin. In the Chicago area, which is, of course, much colder in winter than the Northwest, Geegan finds that a split system is an efficient means to provide overall comfort in condo projects. He installs gas-fired boilers to heat the water that runs through the tubing. The hot water from these boilers also supplies heat to a copper heat exchange coil in the air handler of each condo unit to provide forced hot air heating. The water is distributed to the tubing through copper manifolds. These are closed systems, which offer higher efficiency because the water exiting the under-floor tubing retains some heat on its return trip to the boiler.

An array of copper tubing for melting snow prior to pouring a concrete driveway. This Chicago condominium installation was by Geegan Heating.

An array of copper tubing for melting snow prior to pouring a concrete driveway. This Chicago condominium installation was by Geegan Heating.Geegan obtains his copper tubing (C12200) from suppliers in the Chicago area.

Geegan Heating: 847/593-0123

Tom Marvin: 425/822-8267

Also in this Issue:

- Copper Vital to World Trade

- New "Bronze Age" at Grand Central

- Copper Shines in Radiant Heating

- Copper - Star Energy Saver