Copper Alloy Essential to Bloodless Surgery

The Shaw Hemostatix Scalpel blade contains two layers of high conductivity, high strength copper that use current from the power controller to generate the cauterizing heat. Copper alloy C15725 was specified because it retains its tensile strength when the steel sandwiched between the copper layers is subjected to high temperatures to strengthen its cutting edge.

The Shaw Hemostatix Scalpel blade contains two layers of high conductivity, high strength copper that use current from the power controller to generate the cauterizing heat. Copper alloy C15725 was specified because it retains its tensile strength when the steel sandwiched between the copper layers is subjected to high temperatures to strengthen its cutting edge.Some things never change! Five thousand years ago, cavemen used copper axes as weapons and tools for survival. Today, high tech surgeons save lives and precious blood by using cauterizing scalpels made with copper.

High conductivity and strength are the essential components of the copper metal used in the latest surgical instruments that cauterize (heat seal) blood vessels as they cut. The first of these new instruments is from Hemostatix, Inc. Surgeons around the world are taking to the scalpels because they offer high enough heat for general surgery, they eliminate the risk of burning or electrical shock (problems with circa 1920- designed cauterizing scalpels), and they permit surgeons to work faster, which reduces chances of physical trauma to patients.

Cauterizing scalpels became popular because they minimize blood loss and enable surgeons to see clearly what they are doing. A welcomed by-product is the reduced need for transfusions.

The original cauterizing scalpels are still in use; however, they require the patient to lie on a metal ground plate while heat-inducing electricity passes from the tip of the scalpel through the patient to the ground plate. With this design there's a two-fold risk of burning the patient and shocking operating room personnel.

With the new copper-steel design, the Shaw Hemostatix Scapel, there is no risk of electrical shock, because current does not pass through the patient. The Mountain View, California, company introduced its latest cauterizing scalpels in July 1992. These new versions contain two layers of high conductivity, high strength copper. These precisely controlled elements sandwich a middle layer of steel from which the cutting edge is formed.

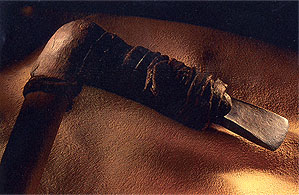

When the body of the "Iceman" was discovered high in the Alps in 1991 at the border between Austria and Italy, a nearly pure copper axe was found beside him. The story on this Bronze Age traveler who froze to death about 4,600 years appeared in The National Geographic, June 1993.

When the body of the "Iceman" was discovered high in the Alps in 1991 at the border between Austria and Italy, a nearly pure copper axe was found beside him. The story on this Bronze Age traveler who froze to death about 4,600 years appeared in The National Geographic, June 1993. Photo courtesy of Ken Garrett

The copper alloy, C15725, from SCM Metal Products of Research Triangle Park, North Carolina, is essential in the new design, according to its developer, Phillip Eggers, because the alloy does not lose its tensile strength when the steel blade portion of the sandwich is subjected to temperatures within 70 F of the copper alloy's melting point during the blade's hardening process.

An earlier Shaw scalpel depended on current travelling through a printed circuit laid down on a sheet of plastic. Because this circuit could not support much power, the scalpel could only be used in very delicate operations, according to Tom Walls, director of operations and production management for Hemostatix. A thick-film circuit in the new scalpel can deliver seven times as much power as the prior design. This provides enough cauterizing heat for general surgery. The new Shaw scalpels are approved by the U.S. Food and Drug Administration.

Blades for the scalpel are fabricated by Telegenix, Cherry Hill , New Jersey . The $25 blades are disposable items and, by law, must be discarded after each operation, Walls said. The sterilizable handles, which cost about $200, can be used for 10 to 15 operations before their electrical contacts wear out. There are on/off and temperature-control buttons in the handle. A ten-foot-long cable leads from the handle to the system's controller, which costs $5,800. The surgeon can also employ the controller to select the temperature of the scalpel before commencing. Walls reported that some 1,000 surgeons in the U.S., Europe and Japan now use the new copper-based scalpel on a regular basis. The device is named after its original inventor, Dr. Robert Francis Shaw, a retired surgeon who owns the company.

Eggers has developed other cauterizing instruments for Hemostatix that employ high conductivity, high strength copper. They are endoscopic devices that permit the surgeon to view what he or she is doing inside the body through fiberoptics. The endoscopic device can be used in the same operation as the scalpel because its power source, the Hemostatix controller, has two power ports into which instruments can be plugged.

The copper alloy used in the new Shaw instruments is supplied by SCM Metals, Research Triangle Park, North Carolina. The major application for the SCM alloy called GlidCop is resistance welding electrodes.Hemostatix: 415/691-0800

SCM: 919/544-8090

Also in this Issue:

- Copper Alloy Essential to Bloodless Surgery

- Copper Highlights Resource Conservation House

- More Copper Equals Big Energy Savings

- Copper and Brass Strengthen Stained Glass