Rigidized Metals Corp. Grows with Textured Copper Metals

"Orders for the copper metals are on the increase in our business," says Richard S. "Sky" Smith, president of Rigidized Metals Corporation, Buffalo, New York. "More and more, architects, who love copper anyway, are moving away from flat copper to textured copper."

The increased favor for copper metals is because of copper's high quality appearance, ease of fabrication, and superior conductivity of both heat and electricity, Smith says.

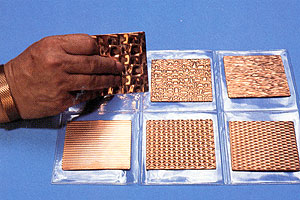

Textured metals are manufactured with dimples, or raised patterns, that add strength, rigidity and abrasion resistance. About 100 different texture patterns and designs are available in copper metals.

Rigidized Metals products, marketed under the Rigid-Tex trademark, are available in sheet, strip and coil, all flat-rolled. Thicknesses range from 0.002" to 0.125". Finishes include: mill, polished, highlighted, vinyl clad, colored and anodized.

Selected samples of Rigidized Metals' deep-textured copper panels

Selected samples of Rigidized Metals' deep-textured copper panelsAccording to Smith, deep-textured metals provide such benefits as: higher strength-to-weight ratio, increased rigidity, reduced weight, improved heat and sound dispersion, superior light diffusion, reduced maintenance, and "slidability," or the ability to drastically reduce surface friction.

Some years ago Rigidized Metals began marketing Solar Rigid-Tex for use in solar collectors. The company had found that textured copper provided more surface area for heat absorption.

"Solar has been away for awhile, but it will be back, with plenty of copper applications," promises Smith.

"A lot of our business is in the copper metals," Smith reports. "Not only is our overall volume increasing, but so is our number of copper metal shipments. Copper metal sales are more significant this year than I can remember."

Much of Rigidized Metals' business is in the elevator cab market. The bronze elevator doors of the International Hotel in Las Vegas are particularly good examples. The doors were manufactured by Watson Manufacturing Company, Inc., Jamestown, New York.

Smith divides his business as follows:

- elevators - "by far the biggest market for us;"

- conveyors - "particularly for the food processing industry."

- aircraft;

- photo equipment - "both photography and copying equipment;"

- transit - "including trucks and buses, especially fire trucks;" and

- the broad area of architecture - "from decorative interiors, such as lobbies and offices, to curtainwall high rises."

Rigidized Metals developed the production of deep-textured metals in 1940. And, according to Smith, "we are one of only two significant companies in the world producing and selling such metals." Rigid-Tex is also manufactured from stainless steel, stainless carbon, nickel alloys and exotic metals such as tantalum and titanium.

For more than 30 years now, Rigidized Metals' prime promotional item has been an attractive textured copper bracelet.

Also in this Issue:

- Biosphere 2 Uses Miles of Copper Tube and Wire

- High-Tech Copper Electrodes Help Cadillac Win Award

- Home of Future - Aglow with Copper and Brass

- Rigidized Metals Corp. Grows with Textured Copper Metals

- Copper Roofing Study Completed

- CDA Offers New Software for Bronze Bearing, Bushing Design

- DecoShield for Fire Sprinklers

- Copper Sculpture Baffles CIA

- Copper Consumer Products Draw Attention, Grow in Sales