Overview

Chromium copper alloys are high copper alloys, containing 0.6 to 1.2% Cr. The chromium copper alloys are used for their high strength, corrosion resistance and electrical conductivity. The chromium copper alloys are age hardenable, which, in this case, means that a change in properties occurs at elevated temperature due to the precipitation of chromium out of the solid solution. The strength of fully aged chromium copper is nearly twice that of pure copper and its conductivity remains high at 85% IACS, or 85% that of pure copper. These high strength alloys retain their strength at elevated temperatures. The corrosion resistance of chromium copper alloys is better than that of pure copper because chromium improves the chemical properties of the protective oxide film. Chromium copper has excellent cold formability and good hot workability. It is used in applications such as resistance welding electrodes, seam welding wheels, switch gears, cable connectors, circuit breaker parts, molds, spot welding tips, and electrical and thermal conductors that require strength. Chromium copper alloys are designated as UNS C18050 through C18600, the cast alloys are C81400 through C81540.

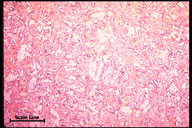

The age hardening reaction occurs because the solid solubility of chromium in copper decreases as the temperature decreases. The structure of slow cooled chromium copper is a two phase mixture of chromium and alpha copper. Superior mechanical properties are achieved by fast-cooling the chromium copper alloys from the annealing temperature, so the chromium remains in a supersaturated solid solution with the copper. Followed by an aging treatment where the chromium precipitates from the solid solution forming a very fine dispersion of precipitates in the matrix. The microstructure of a quenched or quickly cooled chromium copper alloy appears similar to that of the unalloyed copper. A fast cool prevents the chromium from precipitating out of the solid solution, so the resulting cast structure consists of a single phase alpha copper structure. The first material to solidify is pure copper, followed by a eutectic mixture of alpha and chromium. The alpha and chromium eutectic material forms a lamellar structure in the interdendritic regions. The microstructure of the wrought alloy consists of equiaxed, twinned grains of alpha copper solid solution. Typically the allow are cooled rapidly so the chromium remains in alpha copper solid solution. The tempering treatment allows the chromium to precipitate out of solution forming a dispersion of chromium precipitates throughout the matrix. The chromium precipitates, or hardening precipitates, can be very fine and may not be visible at low magnifications.

NOTE: The file size of the Larger and Largest View of the Micrographs are substantially larger than the thumbnail shown. The Larger View images range in size from 11K to 120K depending on the image. The Largest View images range in size from 125K to almost 500K.

|

|

Alloy Family: | High copper alloys |

|---|---|---|

| Product Form: | ||

| Processing: | Age hardened and drawn 20% | |

| Etchant: | ||

| Scale Line Length: | ~ 500Microns | |

| Alloy: | C18200 | |

| Temper: | ||

| Material: | Chromium copper | |

| Source: | University of Florida |

|

|

Alloy Family: | High copper alloys |

|---|---|---|

| Product Form: | ||

| Processing: | Age hardened and drawn 20% | |

| Etchant: | ||

| Scale Line Length: | ~ 250Microns | |

| Alloy: | C18200 | |

| Temper: | ||

| Material: | Chromium copper | |

| Source: | University of Florida |

|

|

Alloy Family: | High copper alloys |

|---|---|---|

| Product Form: | ||

| Processing: | Age hardened and drawn 20% | |

| Etchant: | ||

| Scale Line Length: | ~ 50Microns | |

| Alloy: | C18500 | |

| Temper: | ||

| Material: | Chromium copper | |

| Source: | University of Florida |

|

|

Alloy Family: | High copper alloys |

|---|---|---|

| Product Form: | ||

| Processing: | Age hardened and drawn 20% | |

| Etchant: | ||

| Scale Line Length: | ~ 50Microns | |

| Alloy: | C18500 | |

| Temper: | ||

| Material: | Chromium copper | |

| Source: | University of Florida |

|

|

Alloy Family: | High copper alloys |

|---|---|---|

| Product Form: | ||

| Processing: | Age hardened and drawn 20% | |

| Etchant: | ||

| Scale Line Length: | ~ 25Microns | |

| Alloy: | C18500 | |

| Temper: | ||

| Material: | Chromium copper | |

| Source: | University of Florida |

|

|

Alloy Family: | High copper alloys |

|---|---|---|

| Product Form: | ||

| Processing: | As cast | |

| Etchant: | ||

| Scale Line Length: | ~ 125Microns | |

| Alloy: | C18500 | |

| Temper: | ||

| Material: | Chromium copper | |

| Source: | University of Florida |

|

|

Alloy Family: | High copper alloys |

|---|---|---|

| Product Form: | ||

| Processing: | As cast | |

| Etchant: | ||

| Scale Line Length: | ~ 50Microns | |

| Alloy: | C18500 | |

| Temper: | ||

| Material: | Chromium copper | |

| Source: | University of Florida |

|

|

Alloy Family: | High copper alloys |

|---|---|---|

| Product Form: | ||

| Processing: | As cast | |

| Etchant: | ||

| Scale Line Length: | ~ 25Microns | |

| Alloy: | C18500 | |

| Temper: | ||

| Material: | Chromium copper | |

| Source: | University of Florida |