Copper’s efficient heat transfer inside and outside the tube permits a high heat-exchange capacity to be realized in a compact space, especially using small-diameter copper tubes. These factors result in less materials usage yet higher energy efficiency for appliances and equipment. The long service life of copper tube heat exchangers in these HVACR applications is due to the high strength, excellent durability, and corrosion resistance of the copper tubes.

The copper tubes are interlaced with fins and expanded to improve the thermal conductivity between the tubes and fins. The resulting heat exchangers function as condensers or evaporators in system such as air conditioners, refrigeration equipment and heat pumps, all of which use the vapor compression cycle to deliver either heating or cooling.

Copper versus Aluminum

Proponents of aluminum coils on occasion make claims about “reduced refrigerant charge” and “higher energy efficiency” but a closer examination usually reveals that the latest aluminum coils are being compared to coils made with large diameter copper tubes, which were the norm twenty years ago. This comparison cannot be made for the more superior small diameter copper coils of today.

A more useful evaluation of tube technology would compare aluminum microchannel tubes with copper tubes having outer diameters that are between five and seven millimeters or smaller. Technical literature is widely available on the performance of smaller-diameter copper tubes as well as coils and systems made from such tubes, including comparisons with microchannel technology.

While both are effective heat conductors, copper has a higher thermal conductivity than aluminum. More importantly, copper has excellent durability, including high strength and corrosion resistance.

The Great Coil Debate: A Brief History

OEMs have unsuccessfully attempted to use aluminum tubes for air conditioners since at least the 1980s, but such coils suffered from leaks that were notoriously hard to repair in the field. The success rate was poor.

Around the turn of the millennium, some OEMs sought to repurpose brazed aluminum multichannel (BAM) automotive radiators for air conditioners. The ribbon-like tubes were marketed as an alternative to round copper tubes. The new multichannel or “MicroChannel” technology was received with mixed results. Aluminum round tubes also have not gone away. New coatings have been offered to prolong service life, but the durability of aluminum is questionable while the durability of copper is unmatched.

One feature of aluminum microchannel tubes is that the millimeter-sized channels contribute to a high inside-the-tube heat transfer coefficient (HTC). In other words, in a condensing coil, heat flows quickly from the hot condensed refrigerant through the aluminum tube walls and the serpentine fins sandwiched between the ribbon-like tubes.

Yet, disadvantages of multichannel aluminum were studiously underplayed by its supporters. These disadvantages include maldistribution of refrigerants, large header volumes, difficulty with defrosting and poor drainage. Cleaning of serpentine-style fins squeezed between the ribbon-like multichannel tubes is difficult and fouling and clogging is problematic. Fouling leads also to more corrosion.

Meanwhile, a new technology was emerging. Smaller diameter copper tubes could realize the advantages of multichannel tubes without the disadvantages.

Advantages of Smaller Diameter Copper Tubes

In the past 20 years there has been a gradual evolution in the design of heat exchangers made with round copper tubes. It all comes down to one feature: even smaller diameter tubes. Smaller-diameter copper tubes offer many advantages:

- Smaller diameter tubes withstand higher pressures, allowing for thinner tube walls.

- Smaller diameter tubes allow for the reduction of refrigerant charge.

- Heat exchangers made with copper tubes are easy to repair and service.

- Manufacturing methods are well established for round-tube, plate-fin coils.

- The high recyclability of copper contributes to the circular economy.

- Copper is compatible with many low global warming potential (GWP) refrigerants, which are likely to replace today’s current high GWP refrigerants.

- A high-strength copper alloy is available for high pressure R744 applications.

More recently, copper has been identified as a key material contributing to decarbonization and electrification through the adoption of new heat pump technologies. The manufacture of copper tubes with small diameters and various types of internal enhancements is a well-established technology. Read more about research on reducing refrigerant charge and increasing energy efficiency.

The Purpose of the Inner Grooves

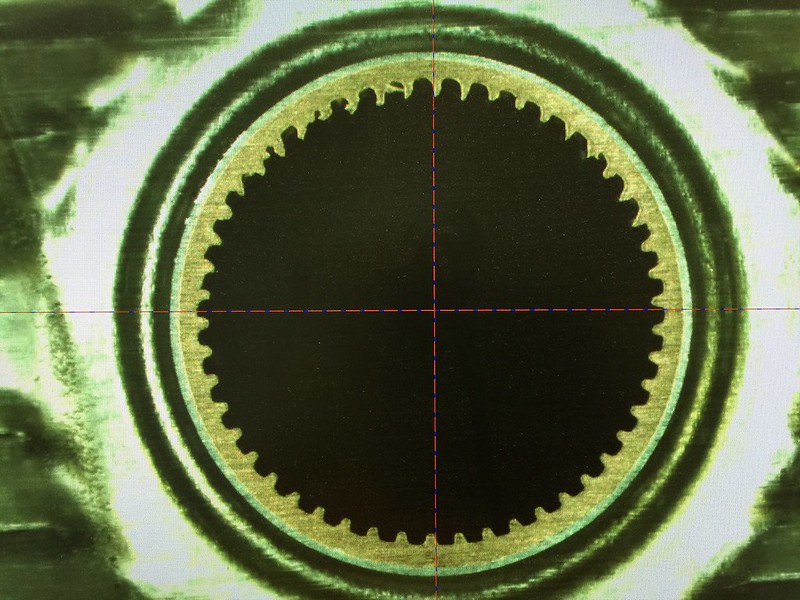

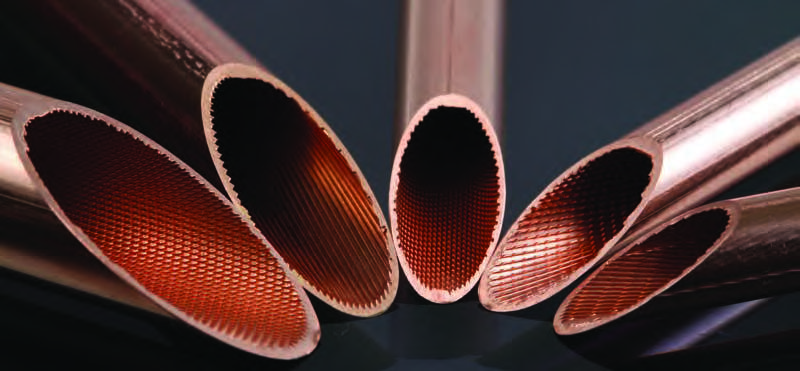

The manufacturing processes for smaller diameter copper tubes lend themselves well to the introduction of surface enhancements on the inside walls of the copper tubes. Such surface enhancements are variously known as inner-grooves or microfins.

The basic principle is that microfins disrupt or break up the laminar flow of refrigerant as it passes through the tubes. As a result, more refrigerant contacts the tube walls. The inside-the-tube heat transfer coefficient (HTC, or alpha “α”) can be measured in the laboratory for various flow rates, pressures, temperatures, and vapor quality (or dryness factor).

Much research has been dedicated to increasing HTCs by enhancing the inside surfaces of tubes. Proprietary enhancements are typically offered by tube suppliers since the introduction of inner grooves and other enhancements is accomplished during the tube fabrication processes.

Learn more about inner grooves in Copper Tube Specifications. [NOTE: link to section 4]

Additional Resources: