Environmental, social and governance (ESG) awareness and expectations are increasingly a concern of officials, policymakers, corporate executives, production managers, and frontline workers.

The copper industry has had an influence on several of the 17 Sustainable Development Goals (SDGs) as set by the United Nations, most notably copper-intensive technologies can have a bearing on the following:

- SDG #6. Clean Water and Sanitation

- SDG #7. Affordable and Clean Energy

- SDG #9. Industry, Innovation, and Infrastructure

- SDG #11. Sustainable Cities and Communities

- SDG #13. Climate Action

Decarbonization and Electrification

Copper will play an essential role in decarbonization and electrification in the following industries:

- Transportation: The transition to electric vehicles will require copper for charging stations and more copper in vehicles compared to internal combustion driven engines.

- Power generation: The build out of renewable energies, including components for solar and wind energy as well as the electric grid, will require vast amounts of copper to fully replace fossil-fuel based electricity generation.

- Building heating and cooling. Copper tube-fin heat exchangers in HVACR will help with decarbonization and electrification in more ways than one.

The application of innovative HVACR technology for heating is promising to advance on the critical path to decarbonization and electrification.

For electrification, there is no road to net-zero carbon without ending reliance on fossil fuels for the heating of buildings. High heat-transfer efficiency arising from the use of advanced copper tube technology in heat exchangers reduces energy demands for heating and cooling of buildings. Homeowners and commercial building owners can decrease dependence on fossil fuels without placing excessive demand on renewables.

The transition to energy-efficient appliances and equipment entails a modest increase in the copper usage (compared to transportation and renewables), yet such appliances and equipment are essential to realizing ESG goals and UN SDG goals.

Some more trends relating to copper in HVACR are as follows:

Greenhouse Gas Reduction

Carbon dioxide is not the only greenhouse gas (GHG). The refrigerants used in many of today’s HVACR products have outrageously high global warming potentials (GWPs). As mentioned in the previous section on applications, advanced copper T-F heat exchangers have enabled the adoption of refrigerants with ultralow GWP. Copper is suitable for use with natural refrigerants such as propane (R290) and carbon dioxide (R744) as well as synthetic refrigerants such as HFOs and HFO blends. In the interim, the use of small diameter tubes decreases the charge requirements for refrigerants such as R32, an HFC with relatively low global warming potential (GWP).

Heat Pumps and COPs

There has been much talk about the advantages of heat pumps compared to gas furnaces and electrical resistance heating. Thermodynamics favors the use of heat pumps. The coefficients of performance (COPs) of typical heat pumps are several times greater than the COPs for gas furnaces or electrical resistance heating. Even at 100 percent efficiency, the COP of a gas furnace or electrical resistance heater is never greater than one.

The COP is simply the ratio of output to input. More precisely, for heating, it is the ratio useful heating coming out of the system divided by the work or energy put into the system. A high COP means high efficiency and low energy (power) consumption.

COPs are highly dependent on operating conditions, including the outdoor temperature. The best systems under mild operating conditions could have COPs around 4.5. Seasonal COP's for heating are typically around 3.5 or less.

Contrary to popular belief, today’s heat pumps can operate at below-freezing temperatures with good efficiency, so they are practical in many more climate zones than previously envisioned. While cold-climate heat pump technology is rapidly developing, small diameter copper tubes are raising the prospect for using heat pumps in the high poluation centers of the Northeast and Midwest, delivering COPs greater than one, even as temperatures dip below freezing (i.e., 0 °C or 32 °F).

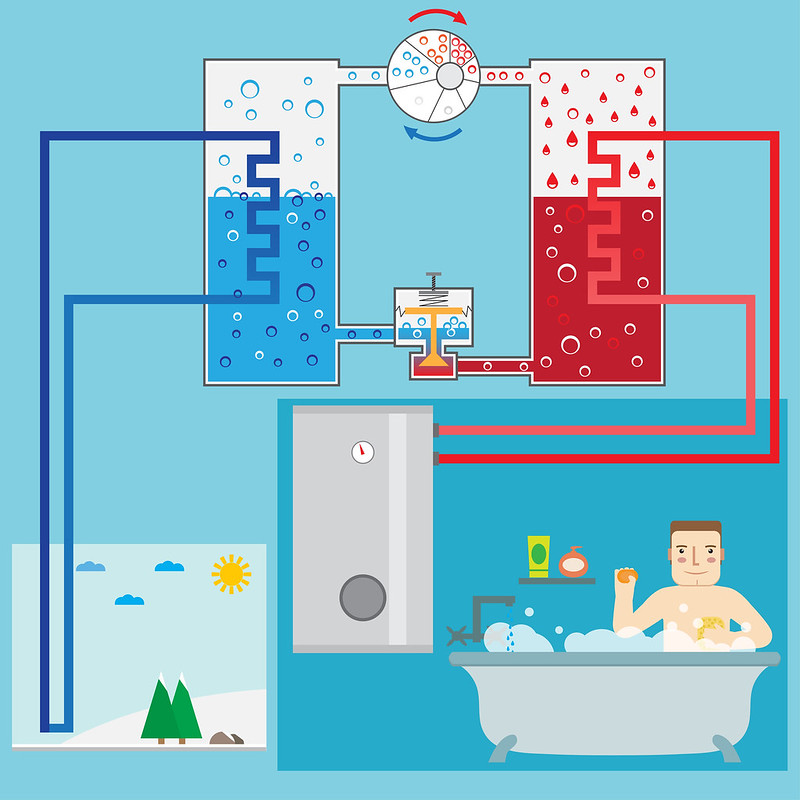

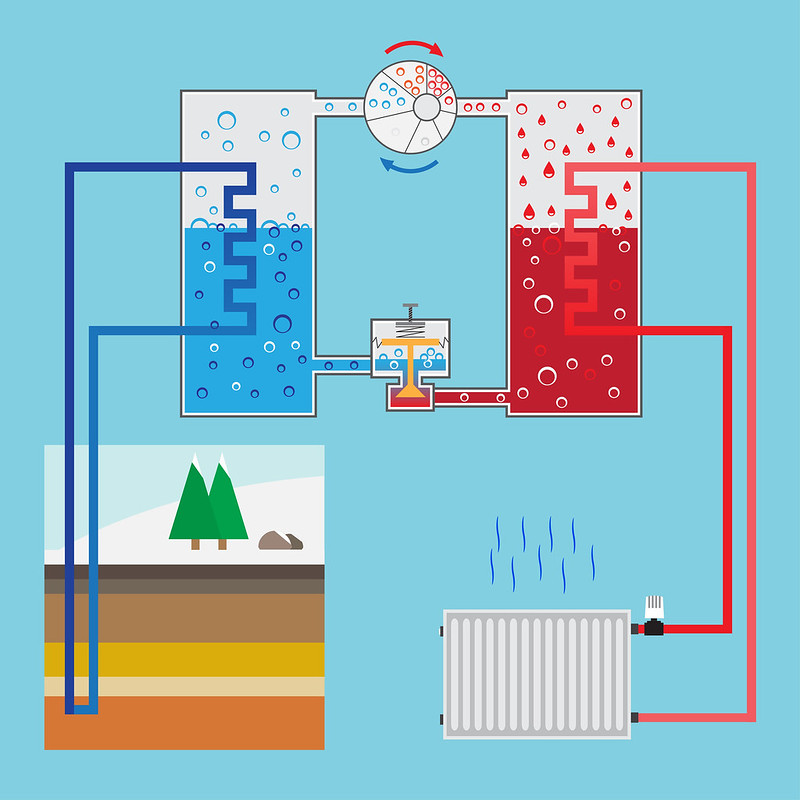

Types of heat pumps include Air-To-Air (ATA) and Air-To-Water (ATW) heat pumps. ATA heat pumps could replace gas furnaces for space heating through a system of ducts. ATW heat pumps could replace boilers for heating water for space heating through a system of pipes and room radiators. ATW heat pumps could also replace gas water heaters for producing domestic hot water.

Thanks to high COPs, heat pumps allow homeowners and building owners to wean off from fossil fuels without placing excessive demand on renewables.

Efficient HVACR Systems

Besides the high efficiencies and coefficients of performance realized using small diameter copper tubes, several other technologies are converging to allow for more efficient operation of HVACR systems. One technology is variable refrigerant flow (VRF). Such systems produce just the right amount of heating and cooling by matching the amount of heating or cooling to the actual needs of the facility, depending on the weather, the building occupancy, and other factors.

Another technology is demand side management. The idea here is to use energy when during off peak hours. For example, water heaters can also be programmed to turn on when the demand on the electric grid is low, essentially acting as an energy storage system.

Another path to efficiency is to use the heating and the cooling together. In other words, an integrated system can use heating from a condenser or gas cooler for heating a building or for water heating. Conversely, the evaporator side of a heat pump can be used for cooling or refrigeration.

Training for the Transition

Another major trend that has been observed is the need to train thousands of new contractors, installers, technicians, programmers, and mechanics to install and maintain new HVACR technologies in the field. The new refrigeration, heat pump and air conditioning systems are often more complex than past technologies and require a higher level of training. The Copper Development Association offers training tools and videos relating to the installation of copper piping for various applications. Read and share the Copper Tube Handbook which provides a wealth of information about copper and copper alloys.

Additional Resources: