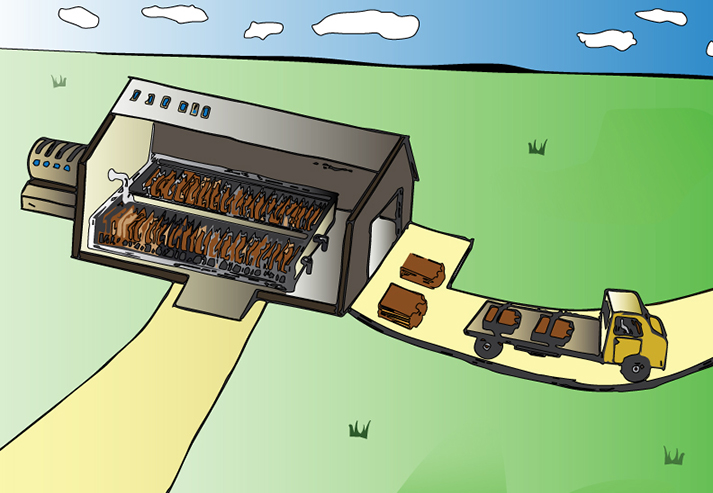

Copper from smelter is cast as anodes

Copper from smelter is cast as anodesThe anodes of 99% pure copper are sent to the electrolytic refinery for purification into very pure copper cathodes. They are immersed into a tank of electrolyte. The electrolyte is an aqueous solution of sulfuric acid and copper sulfate. The copper dissolves off the anode and is plated on the stainless steel, while all impurities remain in the electrolyte. After 7 - 14 days, the transfer to the cathode is complete and it is removed from the tank. The copper is stripped from the stainless steel sheet, washed and shipped to customers. It is now ready to be made into products we all recognize.